A Practical Guide to Soil Stabilization Techniques

- Mike Walker

- Dec 15, 2025

- 16 min read

Before you even think about pouring a foundation or laying a driveway, the ground you're building on needs to be rock solid. It's the silent partner in any construction project, and if it's not up to the task, everything else is at risk.

Why Strong Ground Is a Non-Negotiable Starting Point

Think of it like baking a cake. You wouldn't pour your best batter onto a wobbly, uneven tray and hope for a masterpiece. It just doesn't work. In the same way, not all soil is naturally ready to hold up the immense weight of a building, a road, or a retaining wall.

This is where soil stabilization comes in. It's the engineering process of taking whatever soil you have on-site and improving its physical properties. We're talking about making it stronger, more stable, and ready to handle whatever you build on top of it. It's not just about tamping down dirt; it's a calculated science that actually modifies the ground to perform better for the long haul.

The Core Goals of Soil Improvement

The main goal is simple: turn unpredictable native soil into a dependable, engineered construction material. To get there, we focus on a few key improvements:

Increasing Strength: This is the big one. We need to boost the soil's shear strength and load-bearing capacity. This ensures it can support the weight of buildings or heavy traffic without shifting, settling, or collapsing.

Controlling Volume Changes: Here in Florida, we deal with a lot of clay-heavy soils. These soils expand when they get wet and shrink when they dry out. This constant movement—the "shrink-swell" effect—is what cracks foundations and buckles pavement. Stabilization brings this behavior under control.

Boosting Durability: The process makes the soil far less vulnerable to the elements, especially water. A stabilized base resists erosion and won't break down over time. You can learn more about how to prevent soil erosion on slopes in our detailed guide.

From Ancient Roads to Modern Foundations

Believe it or not, this is hardly a new concept. The idea of strengthening the ground is a time-tested engineering principle that goes back thousands of years. Ancient civilizations like the Mesopotamians and Romans were masters at it. They figured out that mixing things like pulverized limestone into weak soils made them strong enough for roads and pathways—many of which are still around today. That's a serious testament to how effective these techniques are.

In essence, soil stabilization is proactive insurance for your entire project. By investing in the ground first, you prevent catastrophic failures later, such as cracked foundations, buckled roads, and dangerous land erosion.

Ultimately, a strong foundation isn't just a good idea; it's non-negotiable for safety and longevity. In this guide, we'll walk through the different ways to get there—from mechanical and chemical methods to biological ones—so you have a solid understanding of how we build projects that are truly made to last.

Mastering Mechanical Soil Stabilization Methods

Mechanical soil stabilization techniques are the real workhorses of any construction or land development project. Think of them as the fundamental, "brute force" methods we use to physically whip the ground into shape. These approaches don't get into the soil's chemistry; instead, they focus on changing its physical structure to make it denser and a heck of a lot stronger.

At its core, the most common mechanical method is compaction. It’s a simple concept, really. Imagine you’re packing down coffee grounds in an espresso filter before pulling a shot. You press down firmly to get rid of all the air pockets, creating a dense, stable puck so the water can flow through evenly. Soil compaction works on that very same principle.

Using heavy-duty equipment, we apply force to squeeze the soil particles together, pushing out the air and water trapped between them. This process dramatically increases the soil's density, which directly translates to a higher load-bearing capacity. A well-compacted base is your first and best line of defense against future settling and structural headaches.

Choosing The Right Compaction Tools

Not all compaction gear is created equal. Picking the right tool for the job is everything, and it all comes down to the type of soil you're dealing with. Using the wrong machine is like trying to hammer in a screw—it’s just not going to work, and you might even make things worse.

Sheepsfoot Rollers: These rollers are covered in big, peg-like "feet." They are perfect for cohesive soils like the heavy clays we see all over Central Florida. The feet actually knead the soil from the bottom up, forcing out trapped air and ensuring deep, thorough compaction.

Vibratory Plates and Rollers: When you're working with granular soils like sand and gravel, vibration is your best friend. These machines use rapid vibrations to shake the soil particles into a much tighter arrangement, filling in all the empty spaces. They are ideal for creating a rock-solid base for driveways or building pads on our sandy local sites.

Smooth-Wheel Rollers: You'll often see these used as a finishing tool. After the initial compaction is done, a smooth-wheel roller creates a perfectly smooth, sealed surface on top of asphalt or granular base layers.

Proper compaction is a meticulous process that often goes hand-in-hand with other land management services. For example, after clearing dense vegetation, it’s helpful to understand what forestry mulching is and its benefits to get the ground ready for effective stabilization.

Comparing Mechanical Stabilization Techniques

To make sense of it all, here’s a quick breakdown of the common mechanical methods. This table lays out what each technique does, the soil it works best with, and where you'll typically see it in action.

Technique | Primary Function | Best For Soil Types | Common Applications |

|---|---|---|---|

Compaction | Increases density by removing air/water | Clay, silt, sand, gravel | Roadbeds, foundations, retaining walls |

Vibro-Compaction | Densifies loose granular soils using vibration | Sand, gravel | Building foundations, bridge abutments |

Dynamic Compaction | Densifies soil by dropping a heavy weight | Granular soils, landfill materials | Large-scale site improvement, airport runways |

Geosynthetic Reinforcement | Adds tensile strength and separates soil layers | Soft or weak soils | Slopes, retaining walls, unpaved roads |

Each of these tools has its place, and choosing the right one is the first step toward a successful, long-lasting project.

Reinforcing Soil With Geosynthetics

Beyond just packing the soil down, another powerful mechanical approach involves using geosynthetics. These are man-made polymer materials designed specifically for tough civil engineering jobs. Think of them as adding a high-strength skeleton directly into the soil itself.

The core idea behind geosynthetics is to introduce tensile strength—something soil inherently lacks. They act like a net, holding the soil together and spreading heavy loads over a much wider area to prevent localized failure.

There are two main types you’ll run into on a job site:

Geotextiles: These are permeable fabrics that look a bit like heavy-duty felt or a woven tarp. They are mostly used for separation, filtration, and drainage. For example, you might place a geotextile between a new gravel road base and the clay soil underneath to keep them from mixing over time, which helps the road stay intact.

Geogrids: These are grid-like structures with large openings, designed purely for reinforcement. When building a road over soft soil, a geogrid can be laid down to interlock with the stone base, creating a stiff, mattress-like platform that distributes the weight of traffic and helps stop potholes from forming.

When you’re digging into mechanical soil stabilization, it’s critical to understand the proper engineering that goes with it, like how to build retaining walls the right way, to ensure you get lasting ground integrity. These physical solutions really are the backbone of a stable, reliable construction site.

Using Chemical Additives for a Permanent Fix

Sometimes, just moving dirt around isn't enough. When we need a permanent change to the very nature of the soil, we bring in chemistry. Think of it like a baker adding yeast to flour and water—it’s the magic ingredient that transforms a loose mix into a strong, cohesive structure. Chemical soil stabilization works much the same way, introducing additives that kick off reactions to fundamentally alter the soil’s properties for good.

This isn't just about rearranging particles; it's about creating powerful new bonds at a molecular level. The end result is a completely new material that’s stronger, less bothered by water, and far more dependable for any construction project. This approach is a lifesaver for tricky soils, like the expansive clays we see all over Central Florida that just won’t behave with compaction alone.

We’ll dig into the three workhorses of chemical stabilization: lime, cement, and fly ash. Each one has a specific job, and we choose the right one based on what the native soil is made of.

Taming Clay Soils with Lime Stabilization

Lime is the undisputed champion for dealing with those troublesome, fine-grained clay soils. The moment hydrated lime or quicklime hits moist clay, a series of chemical reactions fires up. First, calcium ions from the lime swap places with ions on the clay particles, causing them to clump together in a process called flocculation. This immediately makes the soil less sticky and much easier to work with.

But the real transformation happens over the next few days and weeks. A long-term chemical process known as the pozzolanic reaction takes over. The lime reacts with silica and alumina in the clay to form calcium-silicate-hydrates (CSH) and calcium-aluminate-hydrates (CAH). If that sounds familiar, it should—these are the very same compounds that give concrete its incredible strength.

In short, lime stabilization permanently turns weak, plastic clay into a firm, stable foundation. It drastically cuts down the soil's tendency to swell when wet and shrink when dry, which is one of the biggest culprits behind foundation and pavement failures in our area.

The results speak for themselves. Lime treatment became a go-to technique in pavement engineering back in the 1960s, thanks to research showing just how well it works on expansive clays. Lime-treated soils can see their compressive strength shoot up by 200-300% in a matter of days. At the same time, it can slash plasticity by up to 50% and practically eliminate swelling. You can dive into the foundational research on these impressive gains in soil strength and stability to see the data for yourself.

Creating a Rock-Solid Base with Cement

While lime is perfect for clay, cement is our tool of choice for more granular soils like sands and gravels, although it’s versatile enough to work with a wide range of soil types. When we mix Portland cement with soil and water, it hydrates and hardens into a rigid mass we call soil-cement. The process is simple but the results are powerful.

The cement particles coat the individual soil grains and bind them all together into one solid, durable matrix. The finished product behaves less like soil and more like a low-strength concrete, making it perfect for jobs that demand serious strength and rigidity.

You’ll see us use cement stabilization for:

Road and Pavement Bases: It creates an incredibly tough and stiff base layer that spreads out traffic loads, stopping ruts and potholes before they start.

Industrial Equipment Pads: For sites that need to support heavy machinery, a soil-cement pad provides a solid, unmoving surface.

Slope Protection: We can apply a layer of soil-cement to slopes to shield them from erosion caused by wind and water.

The big win with cement is its versatility and the massive strength boost it provides, turning loose, weak soil into a structural powerhouse.

Fly Ash: A Sustainable Alternative

Fly ash is a fine powder left over from burning coal at power plants. For a long time, it was just seen as industrial waste, but it’s turned out to be an excellent additive for soil stabilization. It functions much like cement, setting off a pozzolanic reaction that forms strong, cement-like compounds when combined with lime or cement.

Using fly ash brings a few key advantages to the table:

Sustainability: It gives an industrial byproduct a new purpose, keeping it out of landfills and making it a more environmentally friendly choice.

Cost-Effectiveness: Fly ash is often cheaper than Portland cement, offering a budget-friendly way to achieve great results.

Improved Workability: It can make sticky clay soils much easier to handle and compact.

We often use fly ash in tandem with lime or a small amount of cement to get the chemical reactions going, creating a stabilized base that is both strong and economical.

No matter which chemical we use, the process is pretty similar: we spread the agent, mix it thoroughly into the soil to the required depth, and then compact the mixture to get it as dense as possible. The final step is proper curing, which is crucial for letting the chemical reactions run their course so the base can reach its full design strength.

Choosing the Right Technique for Your Project

Picking the right soil stabilization technique isn't as simple as grabbing a tool off the shelf. There’s no magic bullet that works everywhere. Instead, it’s a careful process of matching the perfect solution to your project's unique challenges. The ground beneath your feet tells a story, and learning to read it is the first step toward building something that will last.

Think of it like a doctor diagnosing a patient before writing a prescription. A contractor first needs to evaluate the site's specific hurdles, from the type of soil we’re dealing with to how much water it’s holding. Only then can they recommend the most effective and budget-friendly treatment. A method that works wonders on loose sand might be completely useless on wet, sticky clay.

Evaluating Your Site and Soil Type

The most critical factor in this entire decision is the soil itself. Different soil compositions behave in wildly different ways, especially when you put them under pressure or add water. Here in Central Florida, we see a whole spectrum of soil conditions, and each one demands a tailored approach.

Sandy Soils: Common along our coasts, loose sand can fall victim to a dangerous phenomenon called liquefaction, where it basically acts like a liquid under stress. For these sites, mechanical methods like vibro-compaction are often the best bet. This technique uses powerful vibrations to shake the sand particles into a dense, tightly packed state. Chemical stabilization using cement is also a fantastic option, binding the sand grains together to create a solid, unmoving mass.

Clay and Silt Soils: These fine-grained soils are notorious for their shrink-swell behavior. They soak up a ton of water and can turn into a soupy mess, making them nearly impossible to compact properly. For these tricky soils, chemical additives like lime are the go-to solution. Lime permanently alters the clay's chemistry, dramatically reducing its plasticity and tendency to swell.

Organic or Mucky Soils: In areas near wetlands or with a lot of organic content, the soil is often weak and highly compressible. This is where geosynthetics become invaluable. A layer of geotextile fabric acts as a separator between the poor native soil and any new fill material, preventing them from mixing while reinforcing the ground.

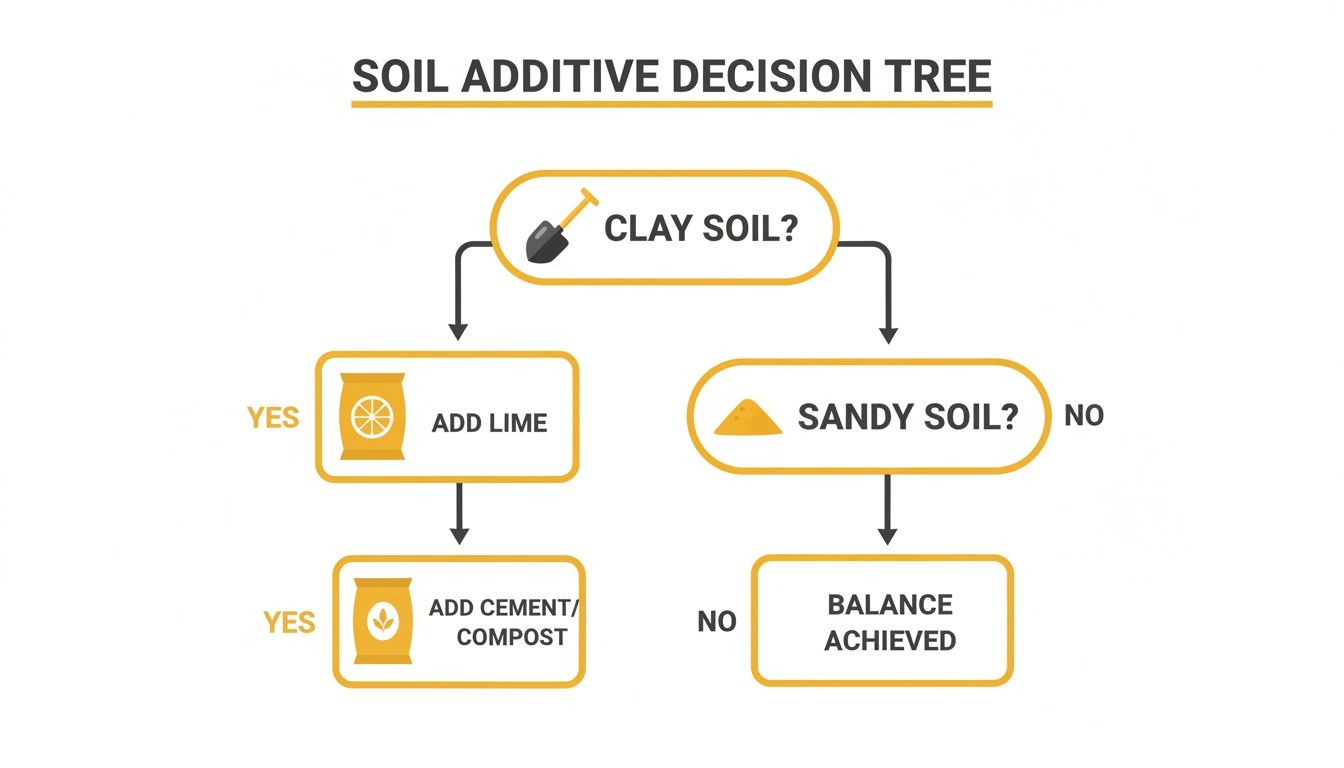

This simple decision tree shows how soil type steers the choice of chemical additives.

As you can see, clay soils respond best to lime, while sandy or mixed soils are a much better fit for cement stabilization.

The Critical Role of Water Management

Water is the natural enemy of stable ground. Too much moisture can turn workable soil into mud, gut its load-bearing capacity, and undermine even the most robust stabilization efforts. Let’s be clear: effective water management isn't just a "nice-to-have"—it's an absolute necessity.

This could mean dewatering the site with pumps or trenches to lower the water table before work even starts. In other situations, the key to long-term stability might be choosing a moisture-resistant chemical additive or installing a proper drainage system using geotextiles. Ignoring water is a recipe for failure.

Real-World Scenario: Foundation on Loose Sand

Let’s bring this all together. Imagine a developer wants to build a commercial foundation on a site with loose coastal sand. A professional from Palm State Clear Cut would kick things off with a geotechnical investigation, which would confirm the soil's low density and high water table.

The recommendation would likely be a two-pronged approach. First, we’d use vibro-compaction to seriously increase the sand's density. Second, we’d mix cement into the top layer of soil to create a rigid soil-cement base. This gives the foundation an unyielding platform to rest on.

This logical, step-by-step process—evaluate the soil, account for the water, and select the right soil stabilization techniques—is how you guarantee a safe and secure structure. For elements like building sturdy and safe Retaining Garden Walls, this level of careful planning is absolutely critical for both safety and longevity. It’s how professionals transform a challenging site into a build-ready property.

Understanding the Costs and Long-Term Value

When it comes to any project, the budget is usually the first thing on everyone's mind. So, "What does soil stabilization cost?" It’s a fair question, but there's no simple flat-rate answer. The final price tag really comes down to what it takes to get the job done right and guarantee a solid foundation.

The specific soil stabilization techniques you choose are a huge part of the equation. Chemical stabilization, for instance, might mean a higher upfront cost for materials like lime or cement. But here's the trade-off: you often save a ton of money by not having to haul away truckloads of bad soil and then pay to bring in expensive engineered fill.

On the other hand, mechanical methods like compaction can have lower material costs. The expense here comes from the specialized heavy equipment and the skilled operators needed to run it. It's always a mix of labor, machinery, and materials.

Key Factors Influencing Your Budget

Beyond the technique itself, a few site-specific details will always shape the project's cost. Any professional estimate will dig into these variables to give you an accurate number.

Site Size and Accessibility: It’s simple math—a larger area needs more material and more man-hours. But accessibility is a big one, too. If heavy machinery can’t easily get onto the site, you might face extra costs for logistics or specialized equipment.

Soil Conditions: The type of soil you’re starting with is everything. Treating Florida's notorious problem clays with lime is a completely different ballgame, and has a different cost, than just compacting sandy soil. A good geotechnical report is worth its weight in gold for accurate pricing.

Required Treatment Depth: There's a world of difference between stabilizing the top six inches for a new driveway and treating soil several feet deep for a commercial building foundation. Deeper treatments demand more material and a much more intensive mixing process.

Shifting Focus to Long-Term Return on Investment

It's easy to get tunnel vision and focus only on the initial quote, but the real story with soil stabilization is its long-term value. This isn't just an expense—it's an investment that saves you from massive, headache-inducing costs down the line.

Think of it this way: The cost of proper soil stabilization is a fraction of what it costs to repair a cracked foundation, repave a sunken driveway, or fix major structural damage from unstable ground. It’s proactive protection for your entire asset.

A properly stabilized base truly is the gift that keeps on giving. It eliminates the risk of settlement, puts a stop to the damaging shrink-swell cycles common in our Florida clay, and creates a durable platform that extends the life of whatever you build on top of it.

The ROI becomes crystal clear when you think about all the repair bills you’ll never have to pay. By tackling the root of the problem—the soil itself—you ensure your project stays safe and solid for decades. That’s real peace of mind.

When to Call in a Soil Stabilization Expert

Look, understanding the basics of soil stabilization is one thing. Actually putting these techniques to work is a whole different ballgame—it's part science, part hard-won experience. It’s like knowing how a car engine works in theory versus actually rebuilding the transmission. Some jobs are just meant for the pros who can stand behind their results.

Knowing when to hang back and make that call is one of the smartest things you can do. Taking a shot at a complex stabilization project yourself can lead to some seriously expensive mistakes, or worse, a catastrophic failure down the road. The ground doesn't give second chances, and a DIY approach on a tricky site is a gamble you really don't want to lose.

Telltale Signs You Need an Expert

There are a few red flags that should immediately tell you a project is out of the DIY league. If you're seeing any of these on your property, it’s time to pick up the phone and talk to a specialist.

Visible Ground Issues: Are you noticing big cracks running through the soil? How about sunken spots that came out of nowhere, or parts of your yard that look like they're slowly sliding downhill? These are all clear signs of deep-seated instability that need a professional eye.

Challenging Site Conditions: Any project on a steep slope, right next to a pond or lake, or on land with a high water table brings major engineering challenges to the table. An expert knows how to handle these complexities safely and correctly.

Heavy Load Requirements: If your plans involve a commercial building, a pad for heavy equipment, or really anything that's going to put a lot of weight on the ground, professional soil stabilization isn't just a good idea—it's non-negotiable for safety and code compliance.

The Value of Professional Execution

Bringing in a team like Palm State Clear Cut gives you a lot more than just access to heavy machinery. You’re getting a complete, science-backed solution from the ground up. An expert makes sure every single step is handled the right way.

A professional site evaluation is the first and most important step in protecting your investment. An expert’s geotechnical analysis removes the guesswork, ensuring the chosen technique is perfectly matched to your soil, guaranteeing long-term stability and preventing expensive future repairs.

It all starts with a proper geotechnical analysis and soil testing to get to the root cause of the problem. From there, an expert can pinpoint the most effective soil stabilization techniques for your specific situation and make sure the job is done flawlessly. This work often goes hand-in-hand with other site prep, and a professional can guide you on maintaining the area afterward. To get a better feel for those initial steps, check out our expert guide for land clearing services in Central Florida.

At the end of the day, the success of your project is built from the ground up. Don't leave the integrity of your foundation to chance. When you spot the signs of unstable soil, getting a professional evaluation is the smartest move you can make to ensure your project is built on solid, reliable ground.

Got Questions About Soil Stabilization? We've Got Answers.

It's one thing to understand the what and how of soil stabilization, but it's the practical, on-the-ground questions that really matter for your project. Let's tackle some of the most common ones we hear from property owners here in Central Florida.

How Long Does Soil Stabilization Last?

This is the big one, and the answer is simple: when done right, it's a permanent fix. Soil stabilization isn't a temporary patch; it's designed to last for the entire life of the road, building, or structure it's supporting.

Think of it this way: chemical agents like lime or cement don't just sit in the dirt; they create brand-new, irreversible chemical bonds. This process fundamentally changes the soil into a solid, durable base that resists shifting and settling. The same goes for high-quality geosynthetics in mechanical stabilization—they provide lasting reinforcement that won’t break down. The goal is always to engineer a foundation that prevents future failures.

Is Soil Stabilization an Eco-Friendly Process?

It absolutely can be, and modern methods are increasingly focused on sustainability. For example, using recycled materials like fly ash—a byproduct from coal power plants—is a fantastic way to strengthen soil while keeping industrial waste out of landfills.

But the real environmental win comes from treating the soil right where it is. The old-school "remove and replace" method is a carbon-intensive nightmare of digging, trucking away tons of bad soil, and then hauling in tons of new fill. By improving the soil on-site, we slash the project's carbon footprint.

This in-situ approach minimizes disruption, reduces emissions, and makes the whole process far more sustainable.

Can Any Type of Soil Be Stabilized?

Just about every soil type can be improved, but there's a catch: you have to use the right tool for the job. There's no one-size-fits-all solution, and what works wonders in one spot could be completely ineffective in another.

Here are a couple of classic Central Florida examples:

Clay-heavy soils, the kind that get slick and mushy, react beautifully to lime stabilization. The lime triggers a chemical reaction that dries out the clay and makes it workable.

Sandy, granular soils, on the other hand, get almost no benefit from lime. For these, something like cement stabilization or vibro-compaction is the perfect match.

This is exactly why a professional geotechnical investigation isn't just a suggestion—it's a mandatory first step. Soil testing tells us what we're working with, revealing the ground's composition and engineering properties. That data allows an expert to prescribe the most effective and budget-friendly solution for your specific site.

Ready to ensure your next project is built on solid ground? The expert team at Palm State Clear Cut specializes in evaluating Central Florida's unique soil conditions and implementing the right stabilization techniques to guarantee long-term success. Contact us today for a free site evaluation and quote

Comments