Master Land Preparation for Building With Key Steps

- Nov 19, 2025

- 13 min read

Site Preparation Checklist For Building Projects

Before the first bulldozer ever touches the soil, you need a clear blueprint of what comes next. In Central Florida, one builder’s crew struck an uncharted water line during grading—and resolving that surprise upfront saved 2 weeks on the build.

A concise checklist keeps every subcontractor on the same page and slashes the odds of costly rework.

Conduct a detailed boundary and topographical survey to map slopes, setbacks, and easements.

Perform environmental scans for wetlands, invasive plants, and protected trees.

Verify underground utilities using GPR scans or markings from utility companies.

Sequence and secure all necessary permits before any heavy machinery moves in.

Recent industry research pegs the global market for site preparation contractors at USD 323.37 billion in 2025, jumping to USD 415.84 billion by 2029 at a 6.5% CAGR. Read the full report about site preparation contractors here.

Marking high-priority zones in advance gives your survey team—and everyone that follows—a clear roadmap.

Clear site maps cut miscommunication and hold crews accountable.

Early Site Evaluation

Your survey data drives everything that follows. Whether you’re using a theodolite or drone-based mapping, accuracy here saves you from backtracking later.

On one job, a topographic study flagged a protected wetland buffer, pushing the pad location downhill. Avoiding that oversight spared the team from costly soil amendments and permit amendments.

Sequencing Clearing And Grading

Clearing and grubbing should flow in stages, stripping brush and stumps only where needed. A smart contractor hauls debris to staging zones beside access roads, keeping haul-truck idle time to a minimum.

When you synchronize tree removal with grading, you avoid juggling crews and trimming schedules.

Optimizing Debris Removal

Efficient debris logistics can shave days off your timeline. For example, an Osceola County project organized brush piles by zone—cutting haul times by nearly 30%.

That kind of planning turns potential bottlenecks into smooth handoffs between phases.

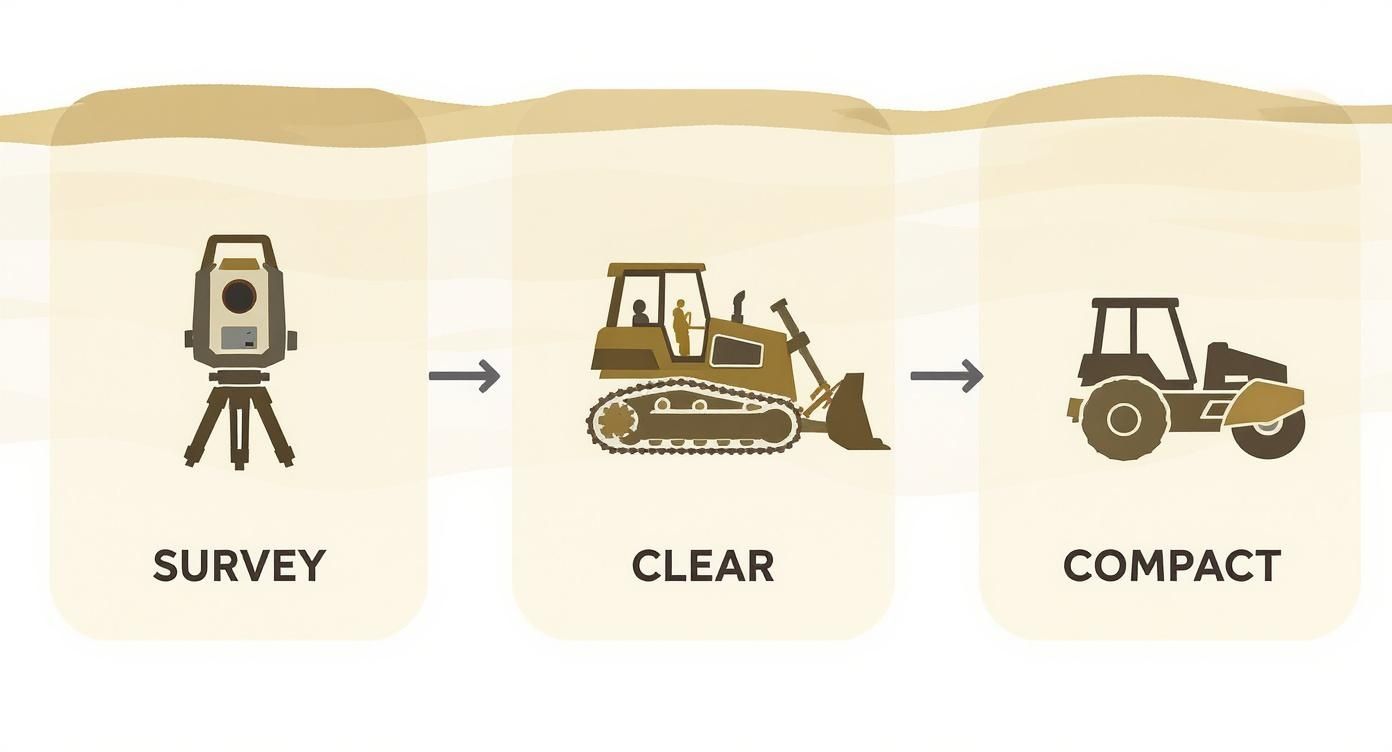

Key Milestones In Land Preparation For Building

The table below outlines the primary goal and typical activities for each critical stage of site readiness.

Milestone | Primary Goal | Key Activities |

|---|---|---|

Survey | Establish Boundaries | Topo mapping, stake placement |

Clearing | Remove Obstacles | Tree felling, brush removal, stump grinding |

Grading | Shape Terrain | Cut and fill adjustments, rough grading |

Compaction | Stabilize Soil | Roller passes, moisture control |

A timeline like this helps everyone understand what comes next and prevents overlapping tasks.

Keeping these milestones in view can cut rework by up to 30% on large builds.

Review this checklist with your contractor during the pre-bid meeting to catch any blind spots. Then let the heavy equipment roll—your foundation will thank you.

Due Diligence And Permitting

Imagine rolling onto a property only to find the boundary markers don’t line up with your plans. A quick review of zoning maps and topographic details keeps budgets intact and timelines on track. Early diligence protects your margins and earns community respect.

No two sites tell the same story. Some parcels hide flood plains, while others sit smack in the middle of a protected habitat. A detailed survey shines a light on those surprises long before equipment arrives.

Key Tasks Before Clearing Ground

Commission a licensed boundary and topographical survey to nail down elevation and setback lines.

Dive into local zoning ordinances to spot height, density, and lot coverage limits.

Run an environmental scan for wetlands, endangered species habitats, or historic landmarks.

Putting these pieces together means your earthwork plan aligns with every rule on the books before a single bucket of dirt moves.

Engaging Local Officials

Forming a rapport with planning staff can shave weeks off approval timelines. On one Polk County project, early coffee meetings cut public hearing waits in half by clarifying submission requirements up front. These conversations also surface local quirks that never make it into online guides.

“Face time with zoning officers kept surprises off the table and saved us $10,000 in redesign fees.” – Local Developer

Moving from survey maps to permit applications may feel overwhelming. Yet getting to know the people behind the process turns complexity into your advantage.

Navigating Permitting Milestones

Kick off permit applications alongside your build schedule. Overlap site plan submissions with utility and erosion control requests so grading and stormwater approvals come through in sync.

Submit site plan and grading permit together to reduce review cycles.

Schedule erosion control and sediment permits before any ground-disturbing work.

Align tree protection or removal permits with your clearing phases.

Permit Type | Typical Lead Time | Key Requirement |

|---|---|---|

Zoning Approval | 2–4 weeks | Site plan, survey, neighborhood notice |

Building Permit | 4–8 weeks | Engineered plans, soil report |

Erosion Control Sign-Off | 2–3 weeks | Silt fence plan, inspection schedule |

Learn more about sustainable site care in Vegetation Management and Why It Matters.

Building Positive Inspector Relations

Inspectors become allies the moment permits land in your hands. Offer clear access paths and share digital logs of progress. One Orlando contractor texted daily weather updates and site photos—cutting idle inspection downtime by 25%.

Regular check-ins and photo logs keep everyone on the same page. That translates to fewer surprises and a seamless handoff to crew leaders.

Case Study In Boundary Accuracy

In Brevard County, a developer used drone LiDAR to verify corner pins. Catching a misplaced stake early saved a full week of re-surveying and sidestepped a potential legal dispute.

Actionable Tip: Host a joint field walkthrough so surveyors, architects, and planners confirm all data in person.

Best Practice: Stake out your foundation footprint right alongside permit docs to prevent expensive layout shifts.

Setting Realistic Timelines

Public hearings and design reviews can drag out if submissions miss key details. Factor in extra time for council meetings or utility easement negotiations. And never underestimate how rain-soaked soils can stall soil testing or stormwater inspections by days.

Reserve at least two extra weeks for unexpected plan revisions.

Coordinate public notice boards early to dodge last-minute reprints.

Track permit expiration dates and set calendar reminders.

By respecting local workflows and building slack into your schedule, you turn permitting puzzles into predictable milestones. Start early, stay flexible, and call in experts to keep your build on course.

Clearing And Grubbing Your Land

Getting the brush out of the way is the first real step toward your dream build. Here in Central Florida, thick undergrowth and invasive species like Brazilian Pepper often hide under every palm frond.

Removing vegetation strategically means balancing speed with preserving property value. This phase turns a tangled lot into a clear workspace—without sacrificing your best shade trees.

Hire an arborist to tag specimens worth saving before heavy machinery arrives.

Map invasive stands of Brazilian Pepper and Air Potato to target removal.

Flag buried obstacles—old concrete slabs or debris piles—that could wreck equipment.

Identifying Vegetation And Obstacles

A thorough walkover survey reveals more than meets the eye. On one Polk County site, crews uncovered concrete slabs buried two feet deep—dodging what could have been thousands in repair bills.

That kind of up-front mapping means you know what lies beneath before the grader ever shows up. It also sets the stage for efficient, safe grubbing.

“Spotting hazards early cut debris hauling by 40%, ” recalls a clearance crew foreman from Osceola County.

Use drone imagery and GPS tags to log dense brush zones.

Cross-reference those areas against topographical surveys to spot hidden wetlands or soft soils.

Selective Tree Removal

Not every tree deserves the chopping block. Preserving mature shade trees can boost curb appeal and slash long-term maintenance.

On an Avocado Ridge project, six live oaks stayed standing thanks to directional felling and tree spades. Local arborists marked each specimen so crews knew exactly where to cut and where to protect.

Rainy season work demands extra care. Seminole County crews paused felling during heavy downpours to prevent rutting and root compaction—saving days of rework later.

Flag removal zones clearly with stakes and bright tape.

Use hand tools for trees under 6 inches in diameter to keep heavy gear idle.

Phase grading to protect the roots of trees you plan to keep.

Stump Grinding And Debris Hauling

Grinding stumps often beats full extraction—especially if you plan to lay sod. By chewing below grade, stump grinders let you compact soil without surprise voids.

Inspect each stump for stability and nearby structures.

Rent a grinder matched to your site; a 35-horsepower unit handles most residential lots.

Collect chips in bins or tarp-lined trucks for easy hauling.

Later, those wood chips can become on-site mulch or erosion control. Recycling biomass typically cuts hauling costs by about 15% and improves soil stability—just spread chips thin so underlying grasses can breathe.

Learn more about alternative approaches in our detailed guide: How to Clear Land Without Heavy Equipment.

Budgeting Regional Cost Variations

In Central Florida, clearing runs about $1,200 to $4,000 per acre. If you’re dealing with dense brush and debris piles, expect costs up to $3,500/acre in places like Osceola County.

Region | Cost Range | Key Factors |

|---|---|---|

Brevard County | $1,200–$2,500 | Sandy soils, hurricane debris |

Polk County | $1,800–$3,200 | Invasive species, wetter soil |

Seminole County | $2,000–$4,000 | Urban proximity, disposal fees |

Permit and disposal fees usually add another $500–$1,500 per acre. Limited-access sites can tack on an extra 10–20% mobilization charge. Always request a written estimate that breaks down equipment hours, tipping fees, and permit costs before signing off.

Safety Best Practices

Protecting your crew and keeping neighbors happy start with a solid safety plan. Full PPE, clear signage, and a 15-foot exclusion zone around moving equipment are non-negotiable.

Brief teams on emergency shutdown procedures every morning.

Maintain daily equipment inspections and logs—small defects can lead to big downtime.

Notify nearby homeowners of heavy-equipment schedules with door-hanger notices.

“A strict safety routine cut incidents by 50% on one Orange County development.”

By weaving tree preservation, equipment planning, clear budgets, and robust safety protocols into your prep, you’ll transform that overgrown parcel into a build-ready pad—without the typical headaches.

Grading Drainage And Soil Integrity

Shaping your lot up front can save you from frustration down the line. Get the slopes right and you won’t fight ponding or soil loss when storms roll through.

In one Central Florida project, a missing 2% incline turned heavy rains into a flooded shell. Lessons like that drive home why grading matters.

Key Grading Techniques

Turning an uneven site into a build pad is all about the right approach. Bench cuts on steep plots create steps that keep soil in place, while laser-guided leveling on flat ground hits uniformity within ±0.1 inch.

Cut-and-Fill Balancing: Shift high spots into low pockets, no off-site hauling needed.

Slope Stabilization: Geotextile layers lock embankments against slides.

Laser-Screed Pads: Guarantee flatness so you avoid costly reworks.

Smart grading can prevent up to 80% of foundation water incidents.

Fine-tuning these methods for your soil and topography lays a drainage blueprint you can trust.

Evaluating Soil Integrity

Before concrete ever touches the ground, know what you’re building on. Geotechnical borings in a grid across your pad map out weak layers and bearing strengths.

Drill 2- to 4-inch cores at intervals.

Pull samples every 5 feet for Atterberg and Proctor tests.

Match lab data to your slab and footing specs.

If clay or organic matter shows up, remediation becomes non-negotiable:

Lime/Cement Treatment strengthens plastic clays.

Stone Columns boost capacity in soggy soils.

Engineered Fill swaps out debris for factory–blended aggregate.

Compact each lift to 95% relative compaction and you’ll lock in the support your foundation needs.

Designing Effective Drainage

Water is relentless—guide it away before it undermines your work. A drainage plan in CAD should mark swales, grade arrows and discharge zones.

Erosion‐matted swales slow flow, trap sediment.

Mulch berms soak up silt and reroute overland runoff.

Catch basins & French drains scoop up subsurface seepage.

Install these controls before the rainy season hits. Hydroseeding berms right after grading can cut soil loss by 70% during storms.

Historically and presently, land preparation is foundational to the global construction market, valued at approximately USD 2.15 trillion in 2024 and projected to surpass USD 3.08 trillion by 2033 at a 4.0% CAGR. Learn more about global construction market projections

Check out our guide on sustainable land management benefits in the context of erosion control https://www.palmstateclearcut.com/post/unlocking-the-power-of-mulching-for-sustainable-land-management-benefits

Integrating Site Stability Measures

Grade, soil and drainage don’t work in isolation. Tie them together with periodic transit or GPS checks—catching a sagging pad early beats expensive repairs.

In coastal zones, keep swale outlets above surge levels for hurricane resilience. For slopes steeper than 3:1, soil anchors add extra insurance.

Inspect controls at 25%, 50%, 75% completion.

Add swale risers or outlet weirs ahead of wet season.

A few extra verification steps today can save tens of thousands tomorrow.

Monitoring And Maintenance

After the heavy equipment clears out, the work isn’t over. Monthly inspections—and always after downpours—keep erosion in check.

Use a laser level to confirm design slopes still hold. Look closely for new rills and reseed bare spots within 48 hours.

Clear debris from grate inlets and French drains.

Tighten up loose erosion mats before they fail.

Consistent monitoring avoids costly regrading later and maintains soil stability.

Case Study In Florida Flood Prevention

A Volusia County homeowner learned this the hard way. A missing runout swale flooded a crawlspace in just two weeks.

Retro trenching set them back $15,000 and delayed framing by a month. The fix? A fresh pad at 3% slope plus a chain of shallow French drains.

Key takeaways:

Walk the pad perimeter with a string line before any pour.

Simulate a 1-inch rain event with a garden hose to verify flow.

Coordinate socked drains in footing trenches with your concrete team.

These checks from day one sidestep pricey fixes down the road.

Utility Access And Final Site Preparation

Once grading crews have finished sculpting the pad and drainage channels are set, utility hookups move to the top of the to-do list. Without water, sewer, power, and gas in place, construction teams can end up twiddling their thumbs—and that’s a recipe for delays.

Utility Coordination Scheduling

Coordinating window slots with local utility providers often feels like a juggling act. Inspections, trenching crews, and backfill teams all need to dance in sync to avoid idle time.

In Volusia County, for instance, one Central Florida build halted trench work for two full days simply because the electric provider’s inspection ran late. To sidestep similar hiccups:

Reach out to each utility company at least 60 days before you plan to trench.

Verify easements and mark line locations using digital mapping and 811 locators.

Reserve inspection slots early—and double-check them in writing.

Sequence trench backfill and compaction so crews aren’t left waiting for sign-off.

If you anticipate shutdowns, arrange temporary service lines. That way, your on-site trailers stay powered through the day.

Sewer And Water Tie-Ins

Hooking into municipal water and sewer mains isn’t just about digging a hole. You’ll need a backflow prevention assembly, hydrostatic testing, and all the logs to prove you passed muster.

On a Lake County residential site, looping in a second water main paid off: when an inspector dropped by unexpectedly, the contractor was ready—and shaved three days off the schedule.

Install code-compliant backflow devices.

Perform a full hydrostatic test before you backfill the trench.

Record pressure readings, then share the reports with authorities right away.

Temporary Driveway Design

Keeping heavy equipment moving without tearing up your new pad takes the right approach. A combination of geogrid and crushed stone routinely supports 50-ton loads during peak construction.

Material | Load Capacity | Cost per sq yd |

|---|---|---|

Gravel geogrid | 50 tons | $2.50 |

Turf mats | 10 tons | $1.80 |

Timber mats | 25 tons | $3.00 |

Bury conduits at a uniform depth and paint them bright orange before you start pouring footings. On one Orange County project, geogrid underlay cut driveway repairs by 75% over the course of the build.

Final Stabilization Techniques

Florida’s sandy soils love to shift, especially when the next afternoon shower rolls in. Before inviting the footing crew, lock the pad down with erosion control:

Lay erosion control blankets on slopes steeper than 3:1.

Build mulch berms around the pad edges to trap sediment.

Spread seed and straw on any grassed swales for instant cover.

Re-inspect controls and reapply after every heavy storm.

Using blankets in roadside swales can reduce sediment runoff by 70%—critical when you’re racing against the clock.

“Having utilities on standby and a stable pad saved our foundation crew two days of waiting time,” recalls a Palm State Clear Cut project manager.

While you’re at it, remember that the global market for construction site preparation equipment topped USD 900 million in 2021 and is growing at roughly 6.5% CAGR. For a deep dive, check out the Global Construction Site Preparation Equipment Report.

Prefoundation Readiness Checklist

Verify all utility trenches are backfilled and compaction tested to 95%.

Confirm survey stakes align with the foundation layout drawings.

Clear the pad of debris and inspect for loose soil.

Ensure erosion controls are in place and fully operational.

Share a daily progress log with the concrete crew.

Check that emergency egress paths and equipment zones are unobstructed.

Double-check that your signage steers deliveries straight to the pad entrance for seamless arrivals.

With utilities tied in and site access solid, your property is ready for vertical construction. Remember to update site logs with each step to maintain transparency.

Prep drives smoother foundation work.

Land Preparation For Building FAQ

Getting a building project off the ground always brings up questions about timing and hidden expenses. These FAQs pull from real on-site experience in Central Florida so you can tackle your land prep with clarity and confidence.

Timeline Factors For Preparation

Every site presents its own rhythm. A shaded lot with dense undergrowth moves differently than a cleared plot, while local regulations and weather add their own twists.

For instance, a contractor in Polk County discovered a 3-week delay when a wetland buffer emerged during grading. That’s why a deep-dive site scan matters.

Lot Size Impacts equipment choice and the crew you’ll need.

Terrain Complexity Steeper slopes demand more grading and soil work.

Permit Approvals Local reviews often take four to eight weeks.

Weather Interruptions Central Florida’s afternoon storms can stall progress for days.

Plan for about 15% extra time on your schedule to absorb surprise delays.

Budget Considerations

Seeing line-item costs upfront prevents nasty surprises. Your quote should break out:

Vegetation Clearing

Erosion Control

Grading and Drainage

Soil Compaction

Utility Trenching

In this region, permit fees and debris hauling commonly tack on $1,000–$3,000 beyond raw site work.

Service | Typical Range | Notes |

|---|---|---|

Vegetation Removal | $1,200–$4,000/acre | Varies by species density |

Grading And Drainage | $5,000–$10,000+ | Depends on slope and design detail |

Soil Testing | $500–$1,500 | Lab fees scale with number of borings |

Utility Trenching | $1,000–$5,000 | Distance from main lines drives cost |

Permit Fees | $500–$2,000 | Local codes set the prices |

Adding a 10–20% contingency fund helps cover surprises like invasive plant removal or extra haul-off.

DIY Risks And Pitfalls

Tackling site work on your own can be tempting, but there’s real downside when pros don’t oversee grading and compaction.

Contractors often have to fix DIY pads that suffer from uneven surfaces or poorly compacted soil.

Equipment Hazards Excavators and dozers are not toys—training is essential.

Incorrect Grading Even small slope mistakes lead to major drainage headaches.

Permit Violations Skipping inspections often results in fines and rework.

Trying to save on labor can backfire when correction costs outstrip initial savings.

Common Mistakes To Avoid

Overlooking key prep tasks can derail your schedule fast. Keep an eye out for:

Inadequate Drainage Water pooling near foundations invites erosion.

Ignored Soil Reports Geotech tests prevent unstable footings.

Overclearing Stripping all trees removes shade and spikes erosion risk.

Permit Gaps Starting early without approvals leads to stop-work orders.

Addressing these before machinery rolls keeps your build on track.

Expert Insight

Bringing surveyors, engineers, and your builder together on a preliminary field walk uncovers hidden utilities, grade breaks, and other surprises.

“Coordinated early site reviews cut our unforeseen utility potholes by 50%,” reports one Central Florida site superintendent.

Land prep lays the groundwork for every construction milestone. Clear timelines, transparent budgets, professional oversight, and avoiding common slip-ups will smooth your path to a solid build.

Ready to turn your property into a ready-to-build site? Reach out to Palm State Clear Cut for a free quote today.

Comments